In the competitive world of the biscuit making industry, understanding the intricacies of the equipment and processes is crucial for success. This guide answers frequently asked questions about Industrial Biscuit Making Machines, helping you navigate through the complexities of the Biscuit Production Line and Automatic Biscuit Production Machine Manufacturers. Whether you’re a seasoned professional or a newcomer, this comprehensive guide will provide valuable insights into the Biscuit Making Machine Industry.

1. What is an Industrial Biscuit Making Machine?

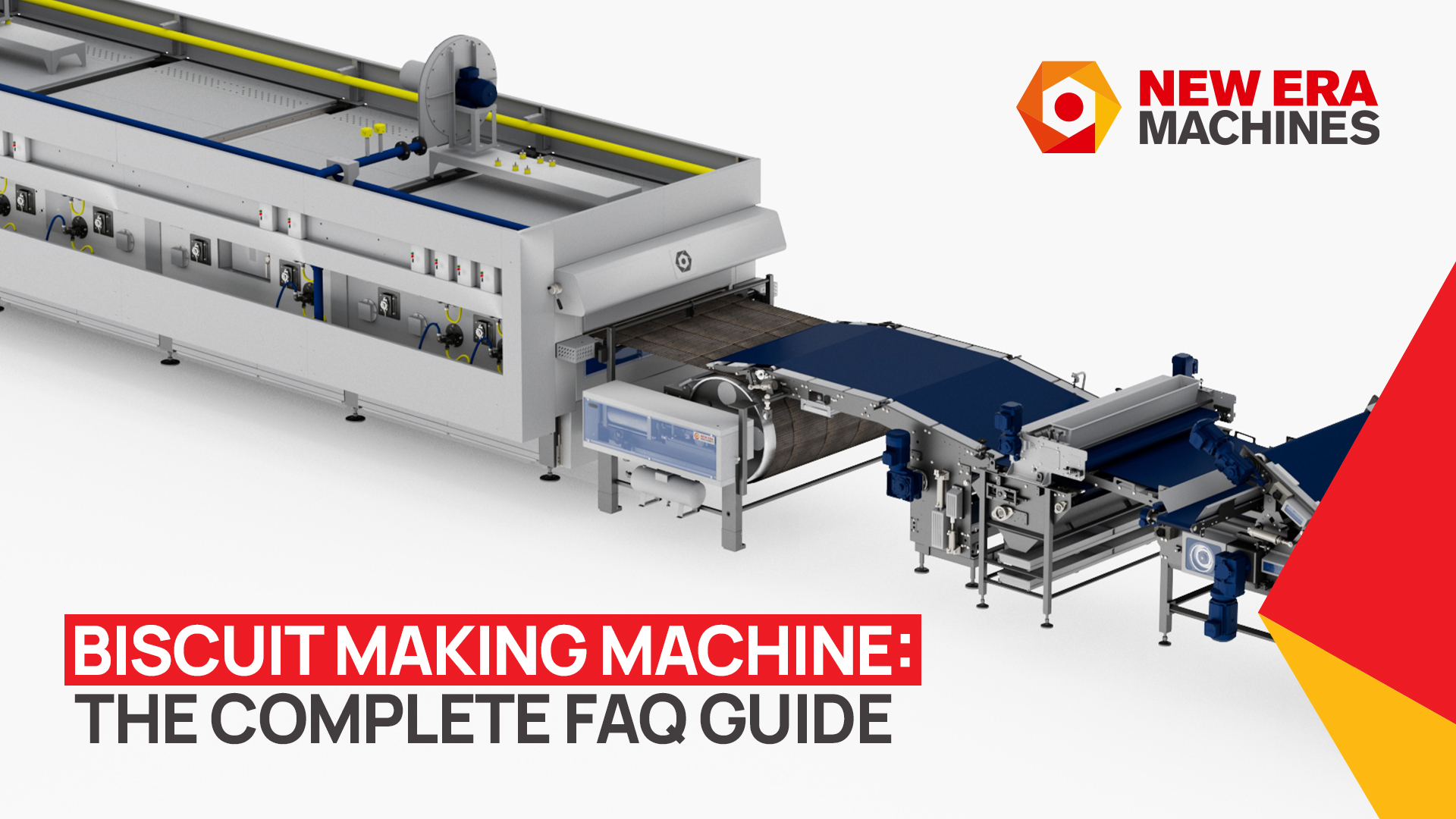

An Industrial Biscuit Making Machine is a specialized piece of equipment designed for large-scale biscuit production. These machines are engineered to handle high volumes of dough, ensuring consistent quality and efficiency in the manufacturing process.

2. How does a Biscuit Production Line work?

A Biscuit Production Line is a series of interconnected machines and processes that transform raw ingredients into finished biscuits. The line typically includes dough mixers, sheeters, molders, ovens, and packaging machines, all working in harmony to produce biscuits at high speed and efficiency.

3. What are the key features to look for in a Biscuit Making Machine?

When choosing a Biscuit Making Machine, consider the following features:

Capacity:

Ensure the machine can handle your desired production volume.

Versatility:

Look for machines that can produce various types of biscuits.

Automation:

Higher levels of automation can reduce labor costs and increase efficiency.

Quality:

Robust construction and reliable components are essential for long-term operation.

Support:

Opt for manufacturers that offer excellent after-sales support and maintenance services.

4. Who are the leading Automatic Biscuit Production Machine Manufacturers?

Some of the leading Automatic Biscuit Production Machine Manufacturers include:

Baker Perkins:

Known for their high-quality, versatile biscuit making equipment.

GEA Group:

Offers comprehensive solutions for the biscuit making industry.

SOTECMA:

Specializes in fully automated production lines.

Reading Bakery Systems:

Provides advanced technology and innovative designs for large-scale biscuit production.

5. How can I optimize my Biscuit Production Line for efficiency?

To optimize your Biscuit Production Line, consider the following tips:

Regular Maintenance:

Keep machines well-maintained to avoid downtime.

Training:

Ensure staff are well-trained on machine operation and troubleshooting.

Automation:

Invest in automated systems to streamline processes and reduce manual intervention.

Quality Control:

Implement stringent quality control measures to maintain product consistency.

6. What are the benefits of using automated Biscuit Making Machines?

Automated Biscuit Making Machines offer several benefits, including:

Increased Production Speed:

Automation significantly boosts production speed, meeting high demand.

Consistency:

Automated machines ensure consistent size, shape, and quality of biscuits.

Labor Savings:

Reduces the need for manual labor, lowering operational costs.

Precision:

High precision in ingredient measurement and processing ensures superior product quality.

7. What types of biscuits can be produced with an Industrial Biscuit Making Machine?

Industrial Biscuit Making Machines can produce a wide variety of biscuits, including:

Hard Biscuits:

Such as digestive biscuits and crackers.

Soft Biscuits:

Including cookies and soft-baked varieties.

Filled Biscuits:

Biscuits with cream or jam fillings.

Decorated Biscuits:

Biscuits with chocolate coatings or icing decorations.

8. What factors should be considered when setting up a new Biscuit Production Line?

When setting up a new Biscuit Production Line, consider:

Space Requirements:

Ensure you have adequate space for all equipment.

Power Supply:

Check the power requirements of all machines and ensure your facility can support them.

Workflow Optimization:

Design the production line for optimal workflow, minimizing bottlenecks.

Compliance:

Ensure all equipment and processes comply with local food safety regulations.

9. How can technology improve the Biscuit Making Machine Industry?

Technology can improve the Biscuit Making Machine Industry in several ways:

Advanced Sensors:

For precise control and monitoring of the production process.

IoT Integration:

Real-time data collection and analysis for predictive maintenance.

Automation:

Reducing human error and increasing production efficiency.

Sustainability:

Innovations in energy-efficient machines and eco-friendly materials.

10. What are the common challenges faced in the Biscuit Making Machine Industry?

Common challenges in the Biscuit Making Machine Industry include:

Maintaining Consistency:

Ensuring consistent quality across large batches.

Equipment Downtime:

Minimizing downtime through effective maintenance and quick repairs.

Keeping Up with Demand:

Scaling production to meet market demands without compromising quality.

Regulatory Compliance:

Staying up-to-date with changing food safety regulations.

Understanding the various aspects of Industrial Biscuit Making Machines and the Biscuit Production Line is essential for anyone in the Biscuit Making Machine Industry. By choosing the right equipment, optimizing production processes, and leveraging advanced technology, you can ensure efficient and high-quality biscuit production. This guide serves as a comprehensive resource to help you navigate the complexities of large-scale biscuit manufacturing.