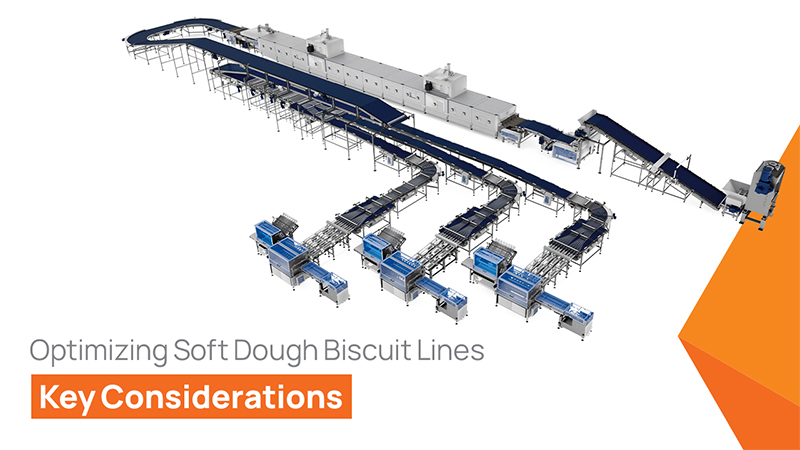

Soft dough biscuits are known for their delicate texture and rich flavours. However, when it comes to their production, achieving consistent quality can be quite a task. From selecting raw materials to final packaging, every step in the production line requires precision to ensure uniformity, minimize waste, and maximize efficiency.

In today’s competitive market, as the demand for soft biscuits increases, it becomes even more important for manufacturers to stay competitive and optimize soft dough biscuit lines. In this blog, we will explore the key considerations that can help streamline soft dough biscuit production.

Key Factors for Optimizing the Soft Dough Biscuit Line

- Raw material selection and quality control

- Dough mixing and hydration management

- Forming and shaping consistency

- Baking temperature and timing precision

- Humidity control during baking

- Cooling techniques for texture preservation

- Packaging to maintain freshness

- Workforce training and operational safety

Raw Material Selection and Quality Control

The quality of raw materials used in soft dough biscuit production determines the quality of the end product. High-quality flour, fats, sugars, and other ingredients ensure better dough texture and uniformity, giving improved biscuit softness and flavour. In soft dough biscuit manufacturing, it is imperative to source ingredients that meet strict specifications and maintain consistency in their characteristics.

Dough mixing and hydration management

Achieving the right proportion of dough mixing is crucial as it directly affects the texture and mouldability of the dough. Precise control over mixing times, temperatures, and hydration levels is essential to avoid overmixing. For an optimal biscuit moulding line setup, the dough needs to maintain a uniform consistency to ensure it flows smoothly through the shaping process thereby reducing waste. Proper hydration management helps maintain the dough’s softness and elasticity throughout production.

Forming and Shaping Consistency

Consistency in forming and shaping is vital for ensuring that every biscuit meets the desired size, thickness, and texture. In soft dough biscuit lines, equipment such as rotary moulders, and sheeters must be calibrated accurately to handle the dough gently. Regular adjustments to the machinery ensure uniform biscuit formation, reduce product waste, and maintain high production efficiency.

Baking Temperature and Timing Precision

Precision control of baking temperature and timing ensures soft dough biscuits with the right texture, moisture content, and flavour. Even slight deviations in temperature or baking duration can result in overbaked, dry biscuits or underbaked, doughy centers. Maintaining consistent heat distribution in the oven is essential to see that biscuits are made uniformly across the entire line.

Humidity Control During Baking

Proper humidity control sees to it that soft dough biscuits retain their moisture and texture. Too little humidity can result in dry, brittle biscuits. On the other hand, excessive humidity can make them overly soft and eventually cause cracking. Manufacturer needs to achieve an ideal balance between a soft interior and a stable outer structure.

Cooling techniques for texture preservation

Post baking, cooling is another process to maintain the quality of soft dough biscuits. In a soft biscuits production line, rapid but controlled cooling helps prevent moisture condensation, which can lead to sogginess or loss of crispness. Ensuring that biscuits cool evenly before packaging also helps maintain their softness without compromising their structure. In addition to this, effective cooling techniques can also help extend the shelf life of biscuits.

Packaging to Maintain Freshness

Good packaging is vital for keeping soft dough biscuits fresh and intact, especially in a biscuit production line where quality must be maintained from production to sale. Using materials that block moisture, air, and light helps prevent the biscuits from going stale and protect them from damage.

Workforce training and operational safety

For any biscuit production line manufacturer, training the workforce is a key element. Well-trained employees understand how to operate machinery effectively, recognize potential hazards, and respond appropriately to emergencies. If a manufacturer invests in workforce education and regular training sessions, then that can ultimately lead to a more efficient production line and higher-quality biscuits.

Final Thoughts

From the above points, it is pretty easy to understand that optimizing soft dough biscuit production lines is essential for manufacturers. As the industry continues to evolve, implementing the above considerations will help improve operational performance for the manufacturer, ultimately satisfying customers.

We hope the article helped you understand and get an idea of key factors to streamline soft dough biscuit lines.