Mixing Systems

Driven by direct drive mechanism and immense capacity from 70-1000kg/batch, our impressive mixing systems compress, knead & monitor dough to provide the required consistency products like soft dough biscuits.

Soft dough biscuits comprises the best-known moulded biscuits. Depending on your requirement the biscuit can be wire-cut, extruded or deposited like cream sandwich biscuits, coconut biscuits, short bread biscuits & choco chip biscuits among others.

New Era Machines designs & develops turnkey industrial rotary molding machines & production lines that deliver high quality moulded soft biscuits with optimum yield & efficiency.

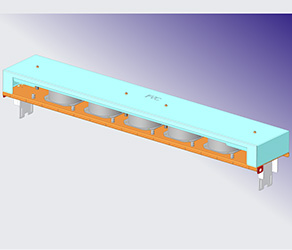

Soft dough biscuit production requires automated feeding systems with a modular design that can be customized according to capacity and line requirements. Our engineering minds have crafted a feeding system that integrates well with the biscuit & cookie production lines to deliver end-to-end performance.

Complete control of knife, pressure & gaps is one of the key factors in the forming stage of soft dough biscuit production. Our modern rotary moulder is added to the production line to produce high-definition, 3d biscuits & cookies while offering complete control. The moulder is equipped to remove excess dough & pass the perfectly shaped dough to the next stage.

Baking is the central step in achieving the perfect final texture and taste of the bakery product. Our acclaimed ovens meticulously control the baking operation & parameters to ensure the consistency of the soft dough biscuits among others. A diverse range of ovens is available to match the customer requirements with precision, quality & performance.

New Era offers an efficient range of post-baking solutions to enhance the end procedures of the baking part of biscuits & cookies like soft dough biscuits. Cooling conveyors along with other systems like turn & packing tables cool help cool, organise & pack the product with ease & make them ready for special applicators section if needed.

New Era Machines has a range of special applicators to accessorize and top flavours on the baking products. This topping helps enhance and augment the taste of the products including soft dough biscuits & cookies and take them to next level. These applicators can be integrated pre and post-baking systems depending on the type of product being manufactured.